Danish architecture studio BIG has completed its own concrete headquarters on an industrial harbour in Copenhagen.

Situated along a pier in the city’s Nordhavn neighbourhood, the 27-metre-tall BIG HQ is wrapped by a protruding staircase that connects its seven floors.

Expansive glazed openings arranged in a checkerboard pattern break up the monolithic form, which is built from Uni-Green concrete.

Uni-Green is a material developed by BIG in collaboration with concrete manufacturer Unicon, which the studio claims emits 25 per cent less CO2 in production than a traditional concrete mix.

The 140-metre-long staircase that protrudes from the exterior is contained within a series of interconnected concrete blocks and provides an external circulation route that doubles as a fire escape.

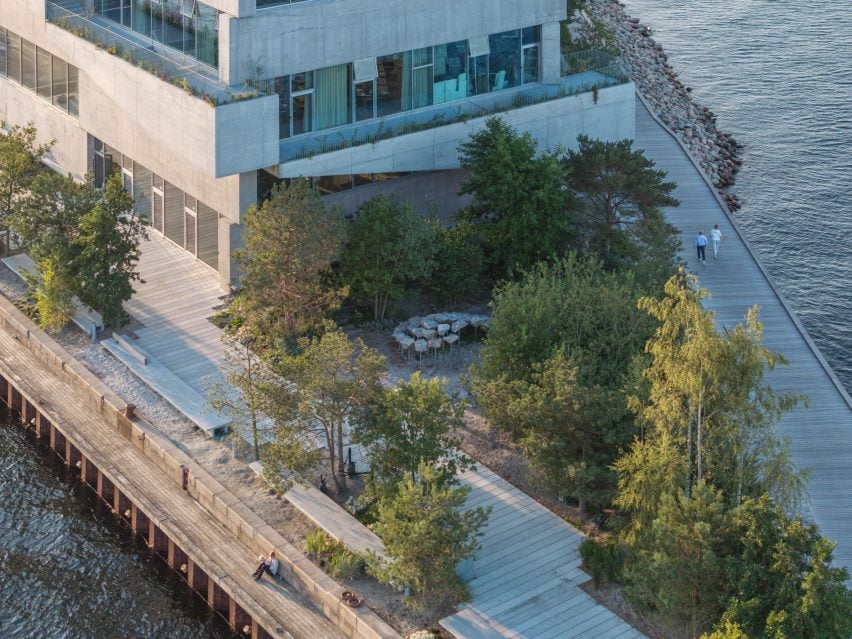

Lined with shrubbery, these concrete blocks also host outdoor terraces at each level before leading up to a spacious roof terrace.

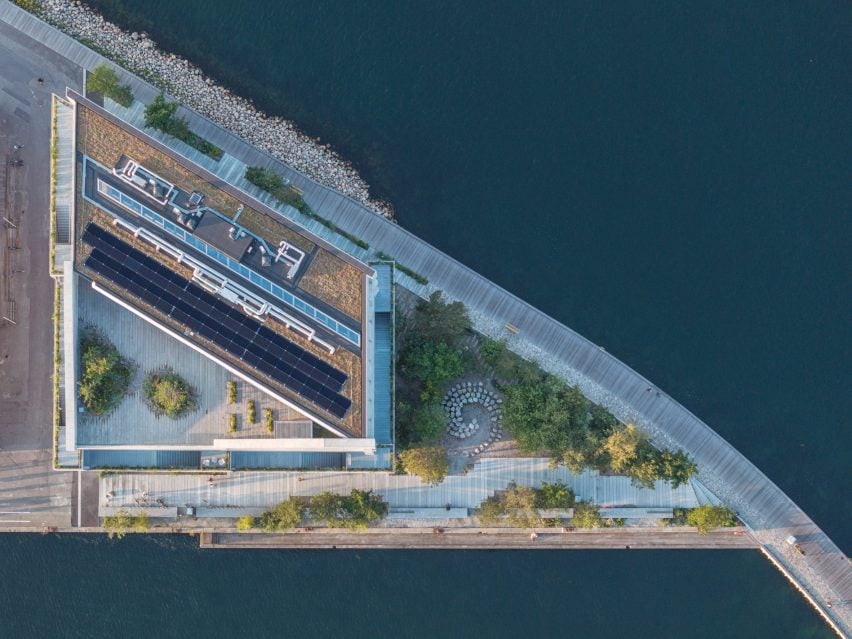

At ground level, BIG HQ sits adjacent to a 1,500-square-metre public park that replaces a former car park. Access to the building is provided by a three-metre-tall glass door.

Inside, employees are welcomed into the spacious open-plan interior by a four-storey entrance area with a zigzagging staircase made from blackened steel.

The staircase rises through BIG HQ to connect its angled concrete floors. A single load-bearing column in the space is composed of six types of stone.

Open-plan offices and workspaces are hosted within the building, with exposed concrete and wooden storage units featured throughout.

BIG has incorporated both solar and geothermal energy systems within the headquarters, which collectively meet 60 per cent of its required energy.

According to the studio, the project is the first realised example of its LEAAP approach – a collaboration between the firm’s landscape, engineering, architecture, planning and product design teams.

“The idea behind LEAPP is an architecture practice as a renaissance, interdisciplinary body of people and knowledge,” said studio founder Bjarke Ingels.

“Every single aspect of LEAPP has been involved in our HQ, including the planning, the product design and the very complex stacking of the concrete elements.”

Other projects recently completed by BIG include the twisting One High Line skyscrapers in New York and its Los Angeles office that is housed within a renovated 1920s building.

Elsewhere, Van Laethem Architecten recently used hempcrete to create its own studio in Belgium while A6A converted a model-making workshop in France into its own office.

The photography is by Laurian Ghinitoiu.